Gypsum application and deep

ripping for vineyard development

Alfred Cass & Associates

1700 Maggie Avenue, Calistoga, CA 94515, USA

USA: Phone 707 942 6384; Mobile 707 529 7408; USA: Fax 707 942 1503

Australia: Mobile +61 41 781 0025

Email: amcass@earthlink.net

Introduction

The reason for improving and maintaining optimum soil structure is to

optimise water, nutrient and air availability to vines by making the soil

more porous, softer and more penetrable by roots. The spin off from this

is usually more uniform vineyards that can be managed more easily with

better control of berry ripening, improved productivity and berry quality

and more assured sustainability.

The main tools available for improving soil structure are:

- deep tillage to disrupt hard soil,

- addition of organic matter to stabilise soil aggregates near the surface,

- addition of gypsum to stabilise deeper aggregates created by deep

tillage,

- use of minimum tillage and avoiding repeated, annual disturbance of

surface soil,

- covering the soil surface at all times by growing perennial, fibrous-rooted

cover crops controlled by mowing and/or herbicide application.

These notes briefly describe the use of these techniques

Gypsum

Gypsum, rather than other forms of calcium, is most commonly used to stabilse

soil aggregates because it is readily available, relatively cheap, easily

handled and can be used on most soil types. The main issues relating to

use of gypsum are:

- properties of the various types,

- deciding on when gypsum is required and when not,

- the amount of gypsum to apply,

- the method and timing of application.

Properties of gypsum

Gypsum is a mineral: CaSO4-2H2O but it contains impurities. It is obtained

either by mining or as a by-product of the manufacture of concentrated

phosphate fertilisers and hydrofluoric acid. Gypsum quality depends on

two factors, purity (impurities include water, soil, limestone, salt,

fluoride, etc) and fineness. Ideally purity should be 14 to 16 % sulfur

(S) and more than 80 % should pass through a 2 mm sieve.

Soil properties which indicate a need for gypsum

Gypsum should be applied to soil if one or more of these conditions are

present in soil:

- soil with more than 5% exchangeable sodium (ESP) on the clays, or

saturation extract sodium adsorption (SAR) greater than 6 or 1:5 soil:

water extract SAR greater than 3 (sodic soil),

- where calcium : magnesium ratios are less than 2 (soil is magnesic),

- where the saturation extract electrical conductivity is approaching

or greater than 2 dS/m or a 1:5 soil water extract is approaching or

greater than 0.2 dS/m for sandier soils and 0.3 dS/m for clayey soils

(saline soil),

- soils that disperse in an aggregate stability test,

- subsoils that have massive, distinct blocky or columnar structure

that is firm, hard or rigid,

- subsoils that have pale or light gray, brown or yellow colours or

that show distinct or prominent mottles, particularly if the mottles

are pale or light gray, brown or yellow,

- soils which crust and/or set hard under the influence of rainfall

and irrigation,

- cracking clay soils with large, widely spaced cracks or which seal

and crust after rainfall instead of self-mulching to form small (2 to

5 mm diameter) surface aggregates.

Application rates

For gypsum to act it has to dissolve in soil water. Dissolution rate is

determined by how much rain or irrigation water passes through the soil.

As a rule of thumb, between 100 and 500 mm (4 to 20 inches) of rain or

uniformly distributed irrigation water will be required to dissolve 1

t/ha (900 lb/acre) of applied gypsum, depending on fineness and efficiency

of incorporation. This means that application of 5 tonnes/ha (2 ton/acre)

of gypsum could take as long as 3 years to dissolve completely. For this

reason, in most situations, depending on soil conditions, it is not sensible

to apply more than 5 to 10 tonnes of gypsum (2 to 4 tons) at a time.

If more gypsum is required, establish an annual or biannual application

program of 1 to 2 t/ha (0.5 to 1 ton/acre) of gypsum, spread on the soil

surface in autumn (fall). Soils with poorly structured surface layers

(crusted, hard set, compacted, erodible, cracking), should be dealt with

in the same way. Winter rain will leach the gypsum into the soil.

Gypsum can also be dissolved in irrigation water and applied through

the irrigation system. This is an efficient means of application, but

requires finely milled gypsum and specially designed equipment to mix

the gypsum and water.

When and where to apply gypsum

Apply gypsum in autumn (fall) prior to winter rain, which will dissolve

it and carry it to depth. Dissolution of large amounts is greatly aided

by banding it on the deep rip line and ripping it into the soil. Some

gypsum will be carried down mechanically but more importantly, rainwater

following the preferential path of the rip line will dissolve it and move

it to depth. Disking it in will also improve dissolution rate.

Deep Ripping

Deep ripping of vineyard soils is necessary if there is either a physical

or a chemical root impediment within a depth of up to 1 m (40 inches).

Ripping will disrupt the physical barrier, soften the soil, and allow

roots to exploit the full depth to the limit of deep ripping. It will

also assist in placement of ameliorants such as lime or gypsum and creates

improved drainage for removal of salinity, sodium, or excess water. Available

soil water is also increased because:

- large, water and air storage pores are created at the expense of smaller

pores,

- many larger water transmission pores are created,

- the effective root depth for the vine is increased of softening the

soil,

- penetration of rain and irrigation water is improved.

These benefits will persist longer if gypsum is added to stabilise the

newly created pores and heavy wheel traffic is rigorously excluded from

the vicinity of the rip line.

What soils should be deep ripped?

Deep ripping is indicated if any one of the following factors is present

in the soil:

- hard sheet rock that is shallow (< 50 cm, < 20 inches deep)

and thin (< 30 cm, < 12 inches thick) and which overlies soft,

- porous, well drained material which, after ripping, will not have

more than about 50 % gravel to the lower depth of ripping,

- partially weathered rock within 800 mm (32 inches) of the surface,

particularly if a cemented pan is present and which, after ripping,

will not have more than 50 % gravel to the lower depth of ripping,

- saprolite within 800 mm (32 inches) of the surface, particularly if

a cemented pan is present,

- hard, fine or rubble carbonate layers within 800 mm (32 inches) of

the surface,

- firm, hard or rigid, poorly structured peds (large blocky and prismatic

or massive) within 800 mm (32 inches) of the surface,

- previously compacted agricultural land with a penetration resistance

in excess of 2 MPa at field capacity water content within a depth of

800 mm (32 inches) of the surface,

- saline subsoil (ECse > 2 dS/m or EC1:5 greater than 0.3 for clays

and 0.2 for lighter textures) or sodic (ESP > 6 %, SARse > 6 or

SAR1:5 > 3) or acid (pHCaCl2 < 5) or alkaline (pHCaCl > 9)

(ameliorants need to be added before ripping),

- waterlogged soil where a drainage barrier can be identified within

a depth of 800 mm (32 inches) from the surface.

When to deep rip?

The correct subsoil moisture content is critically important for effective

deep ripping of clay-rich soils. Generally there are only two periods

of the year when this condition can be met: late autumn (sufficient rainfall

to moisten but not saturate subsoil) and late spring (sufficient drying

out but not desiccation of subsoil). Only at these times will the soil

fracture correctly and yield fine (<20 mm, < _ inch diameter) fragments

necessary for optimum root penetration. At other times of the year soil

moisture content is unlikely to be at a level for optimal results. In

summer the subsoil is too dry and clay-rich soil shatters, creating large

clods and fine dust. In winter soil remoulds and compacts because of the

plasticity of wet clay. Sandy, gravelly and rocky soils are less critically

dependent on water content because they tend to be fracture in a brittle

way even when quite wet.

The correct subsoil moisture content for deep ripping is the plastic

limit. This water content lies between field capacity and wilting point.

A sample of the subsoil should be tested by vigorously kneading a handful

of subsoil long enough to break down aggregates and form a ball. If a

ball can be formed it should be broken open and a pinch of soil taken

from the centre and rolled out on the palm of the hand to form a thread.

Shorten the thread if necessary to facilitate rolling. The diameter of

the thread that is obtainable from this procedure predicts what will happen

to the subsoil on ripping:

- If the subsoil rolls out into a thread that crumbles as it approaches

a diameter of 3 mm (1/8 inch), the water content is correct for optimal

results: tensile fracturing and maximum lift of the subsoil to yield

small clods, the majority not bigger than about 20 mm (3/4 inch) diameter,

and a minimum of fine dust.

- If the soil rolls into a thread smaller than 3 mm (1/8 inch) in diameter,

the soil is too wet for optimal fracturing and the subsoil will not

fracture laterally, the effect of ripping may be plastic failure leaving

narrow slots with the main body of subsoil intact and deposition of

large subsoil clods on the surface.

- If the subsoil cannot be worked into a ball that can be rolled into

a thread or if a coarse thread forms that crumbles well before it reaches

3 mm (1/8 mm), the soil is too dry for ripping and the result will be

brittle fracturing of the subsoil leaving many large clods in a matrix

of fine dust.

If gypsum is required for subsoil amelioration, broadcast half of the

gypsum on the surface during the autumn prior to ripping. Winter rain

will leach the gypsum into the soil, where, if it reaches the subsoil,

a degree of softening can be expected, and a better ripping product achieved.

If the soil is to be ripped in late spring, sow a cereal crop to stabilise

the soil through winter and use the winter rainfall. This will provide

the means to control soil wetness at the time of ripping in spring. If

ripping is done in autumn, and a year’s lead in time is not available,

apply up to 5 tonnes/ha (2 ton/acre) of the gypsum requirement on the

rip line and rip the gypsum into the soil. If the gypsum requirement is

over 5 tonnes/ha (2 ton/acre), broadcast the remainder onto the surface

and work it in during subsequent vineyard preparation.

How to deep rip

The depth of working is important for optimum results. Each ripper blade

has a critical working depth in hard soil, below which the blade will

not fracture the soil laterally, but compact it. Test a section of ripped

soil by digging a trench behind the ripper and examining the soil for:

- no compaction (penetration resistance << 2 MPa),

- correct size of clods (most < 20 mm, < _ inch) diameter),

- minimum amount of dust (most > 0.25 mm, 0.06 inch diameter),

- proper lateral fracturing to give a wide (> 1 m, 40 inches) fractured

zone at the soil surface.

- correct depth of ripping, (up to 1 m, 40 inches), depending on desired

root zone volume and subsoil conditions.

Do not proceed with ripping if all these factors are not correct. If

necessary raise the ripper working depth and rip on the same lines more

than once, going progressively deeper with each pass. Alternatively use

a tandem of ripper blades with the rear blades spaced immediately behind

the front ones but working deeper.

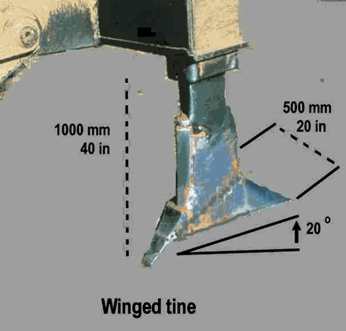

The shape of the ripper blade is important for correct fracturing of

subsoil material. Hard rock, weathered rock, and cemented pans require

a wingless blade with a point having a rake angle of at least 20O. Clay

subsoils require a winged blade (Figure 1) with a 90O point and angled

at 20O for maximum lateral fracturing and maximum lift. The rake angle

of 20O is critical. Tines with a greater rake angle will compact the soil

adjacent to and below the rip line. Tines with angles less than 20O will

not lift and shatter the subsoil. South African experience suggests that

a series of 20O wings spaced down the ripper tine is effective in diffusing

the boundaries of sharply layered soils ("Duplex" soils) without

undue mixing of horizons. The latter needs to be avoided if deep material

has an undesirable effect on shallower soil properties.

Figure 1: Optimum dimensions and rake angle of a winged

tine suitable for deep ripping clay and clay loam soils at the plastic

limit moisture content.

Direction of ripping and spacing of ripper tines depends on the aims

of ripping and the depth and extent of fracturing required. For complete

disruption of an impeding layer, the spacing of the tines must be 2/3

of the final depth of ripping. Ripping only on the row is a cost beneficial

way of establishing vines but will probably not create conditions for

lateral spread of the vine root system into the midrow. This may be an

important consideration in vineyards where irrigation water is limited

and reliance on rainfall storage great.

Recompaction of vineyards is a common occurrence because of the need

to traffic the midrow to prepare for planting, install trellis posts and

subsequently manage the vineyard. Ripping on the row and rigorously avoiding

trafficking the rip line provides an immediate optimum root environment

for the young vine and leaves available the option of ripping wheel tracks

after the vineyard is established.

Closely spaced ripping may preclude trafficability of the vineyard for

some time if wet conditions occur after ripping. Cross ripping at 90O

may also create conditions of excessive soil wetness. In general, the

direction of travel during ripping should be down slope to facilitate

natural drainage. If cross ripping is necessary, excessive wetness can

be reduced by cross ripping at 60O with the intersecting rip lines running

down slope.

Other important points that need to be considered are:

- the power of the tractor or the depth of ripping must be such that

wheel or track slippage is minimised to prevent damage to surface soil

structure,

- the speed of travel should be slow, less that 5 km/h (3 miles/hour),

- use a section of railroad track dragged behind the ripper to smooth

the surface, not the tractor blade,

- avoid driving heavy machinery on the rip line.

Immediately after deep ripping the surface soil should be prepared for

sowing a cover crop and incorporating the remaining amendments, fertiliser

and on-row organic matter. At this time secondary wheel compaction can

be eliminated by using deep working tines behind the tractor wheels..

A set of tines (up to 300 mm, 12 inches deep) behind the wheels of heavy

tractors wheel will prevent further compaction. Do not use of a rotary

hoe to finish off land preparation, rather disking with the tractor wheels

straddling the rip line.

A cover crop should be sown immediately after ripping, particularly on

steep land. Generally, a grass or cereal cover crop is ideal for controlling

erosion and stabilising the beneficial soil structure created by ripping

and tillage. The cover crop should be controlled by coarse mowing rather

than fine slashing, to provide a durable surface mulch.

|